The creation of detachable storage rack furniture and side tables represents a fascinating intersection of modular design and material science. For manufacturers specializing in acrylic fabrication, this process demands exceptional precision while offering users unprecedented flexibility.

Fabrication Process: Engineering for Assembly

The manufacturing journey begins with digital prototyping. Using 3D modeling software, designers create components with interlocking features that will snap together without additional hardware. The brilliance of this approach lies in the precision of the connection points - each tab and slot must be engineered to within millimeter tolerances.

Laser cutting brings these digital designs to life. High-powered CO2 lasers trace intricate patterns through acrylic sheets, creating clean edges that require no additional finishing. The laser's heat actually polishes the cut edges as it works, resulting in smooth, crystal-clear finishes. What makes this process unique for modular furniture is the creation of living hinges - thin sections of acrylic that remain flexible, allowing panels to bend and lock into position.

For more complex joining systems, manufacturers employ ultrasonic welding. This technique uses high-frequency sound waves to fuse acrylic components at the molecular level, creating bonds that are often stronger than the material itself. The result is a seamless connection that maintains the optical clarity of transparent pieces.

Practical Advantages: Beyond Conventional Furniture

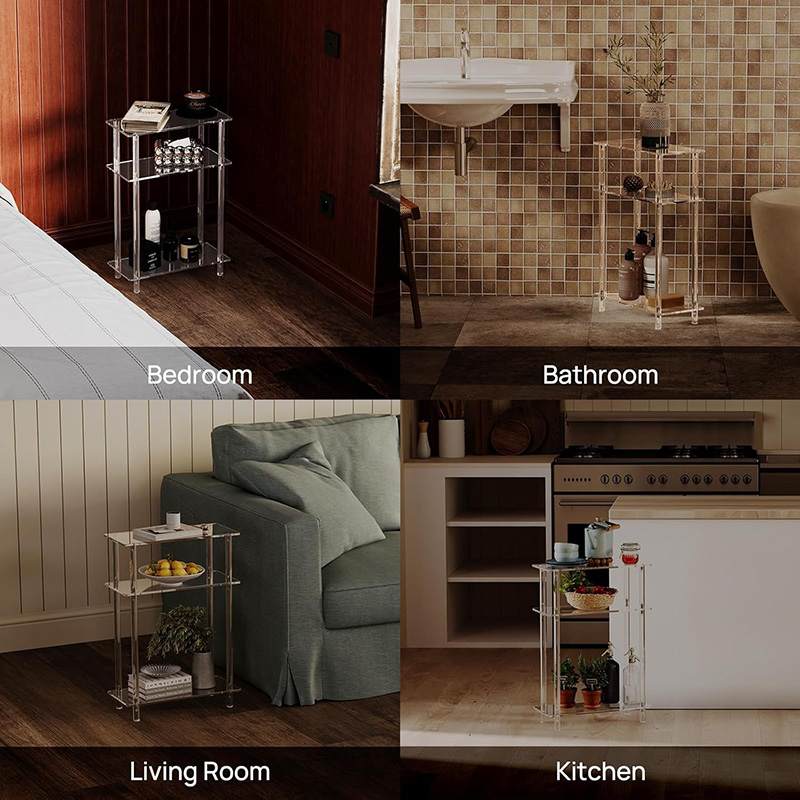

The benefits of these customizable systems extend far beyond their aesthetic appeal. The modular nature allows users to reconfigure their storage solutions as needs change - a bookshelf can transform into a display case, or a side table can expand into a multi-tiered organizer. This adaptability makes the furniture ideal for dynamic living spaces where requirements evolve.

From a practical standpoint, the knock-down design revolutionizes transportation and storage. These pieces ship flat, reducing packaging materials and shipping costs by up to 70% compared to pre-assembled furniture. For urban dwellers and frequent movers, this represents a significant advantage.

The material properties of acrylic contribute to exceptional durability. Unlike wood that can warp or metal that may corrode, high-grade acrylic maintains its structural integrity and appearance through years of use. The non-porous surface resists stains and moisture, making these pieces suitable for various environments from bathrooms to kitchens.

Manufacturers can incorporate custom elements through techniques like digital printing or laser engraving, allowing for personalized patterns, logos, or organizational labels. This level of customization transforms standard storage into bespoke organizational systems that reflect individual style and needs.

Perhaps most importantly, the assembly process requires no tools or specialized skills. The precision-engineered components snap together intuitively, creating sturdy furniture in minutes. This user-friendly approach eliminates the frustration commonly associated with furniture assembly while ensuring perfect alignment every time.

Through sophisticated fabrication techniques and thoughtful design, these acrylic storage solutions represent the next evolution in functional furniture - pieces that are as practical as they are beautiful, and as adaptable as they are durable.